Overload Protector Pump

Price 38500 INR/ Piece

Overload Protector Pump Specification

- Head Size

- 15~40 meters

- Inlet/Outlet

- 1 inch BSP Thread

- Max Suction

- 8 meters

- Voltage

- 220-240 V

- Caliber

- 25 mm

- Flow Rate

- 2~6 m3/h

- Theory

- Electromagnetic Pump Principle

- Working Temperature

- -10C to +50C

- Speed

- 2900 RPM

- Control System

- Manual

- Mounting Type

- Base Mounted

- Frequency

- 50 Hz

- Noise Level

- Less than 70 dB

- Features

- Built-in automatic overload protector, corrosion-resistant body, thermal protection, easy installation

- Discharge Pressure

- Medium Pressure

- Material

- Cast Iron and Brass

- Structure

- Horizontal

- Power

- 0.37~1.5 kW

- Standard

- IS 9079

- Fuel Type

- Electric

- Pressure

- 0.7~4 Bar

- Usage

- Water/Fluid Transfer

- Application

- Domestic, Industrial, Agricultural

- Suction Type

- Single Suction

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Centrifugal

- Capacity

- 4000~6000 LPH

Overload Protector Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 3-4 Days

- Packaging Details

- Boxes

- Main Export Market(s)

- Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia, North America, Australia

- Main Domestic Market

- All India

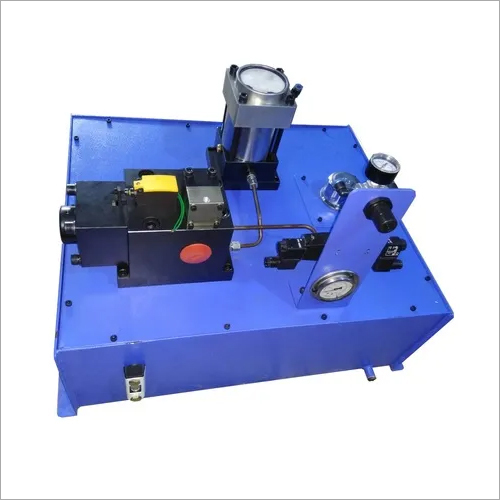

About Overload Protector Pump

Overload Protector Pump - 600 Ton

We are manufacturer and stockiest of Hydraulic Overload Protector Pump for Mechanical Presses. We have replacement of wide range

|

for reputed makes like SANDSUN ( TAIWAN ), PASCAL ( JAPAN ), KOSMEK ( JAPAN), KONAN ( JAPAN ), SAE JIN ( KOREA ) and KAN-TOU.

-

Overload protector is equipped in press machine to check the hydraulic pressure of cylinder inside the slider.

-

If happened overload, the hydraulic pressure of cylinder will be released

immediately within 3/1000 seconds.

-

When happen overload, in order to protect the press and die, the press will stop working immediately after receiving the signal from limit switch.

-

After happen overload, the air will drive hydraulic pump to supplement normal

working pressure immediately and the press can work normally.

-

It has pressure control valve inside of overload protector. Which can adjust hydraulic pressure automatically and eliminate the impact of rising pressure (which cause by oil temperature rise) in pressing process?

|

AIR SUPPLY(BAR) |

PRESSURE SETTING RATIO |

AREA OF ORIFICE |

PRESSURE SETTING RANGE |

MODEL NO |

CAPACITY |

|

3-5 |

1:50 |

0.7 |

150-250 BAR |

OP03-500 |

UPTO 200 TON |

|

3-5 |

1:70 |

0.5 |

200-350 BAR |

OP03-700 |

|

|

3-5 |

1:90 |

0.4 |

250-450 BAR |

OP03-900 |

|

|

3-5 |

1:50 |

1.7 |

150-250 BAR |

OP06-500 |

UPTO 600 TON |

|

3-5 |

1:70 |

1.2 |

200-350 BAR |

OP06-700 |

|

|

3-5 |

1:90 |

0.9 |

250-450 BAR |

OP06-900 |

|

|

3-5 |

1:40 |

5.4 |

120-200 BAR |

OP10-400 |

UPTO 1200 TON |

|

3-5 |

1:50 |

4.3 |

150-250 BAR |

OP10-500 |

|

|

3-5 |

1:70 |

3.1 |

200-350 BAR |

OP10-700 |

Advantages of Hydraulic Overload Safety Pump:

- Stop Press operation immediately and protect press from major breakdown

- Protect Die during overload situation

- Protect Components

- Easily ejection component from die

- Just single Reset Push Button and resume press operation, save time and increase productivity

- Extend Tool Life also indicate in case tool needs to refurbish

- Reduce connection clearances

- Alert during excessive off-center loads

Advanced Protection and Durability

This pump is built with a protection class of IP44 and insulation class B, providing strong safety against dust and water splashes. Its corrosion-resistant cast iron and brass body, along with reliable mechanical seals, ensure a long operational lifespan, even under rigorous conditions. The integrated automatic overload protector shields the motor from excessive current, reducing the risk of failure and costly repairs.

Efficient Fluid Transfer Capabilities

Designed with a flow rate of 2 to 6 m/h and suitable for medium pressure applications, the pumps impeller made of brass enhances performance for both domestic and industrial scenarios. It features a 1-inch BSP thread inlet/outlet, self-priming capability, and can achieve a maximum suction lift of 8 meters, making it ideal for various water and fluid transfer needs.

Easy Installation and Versatile Application

The pumps horizontal, base-mounted structure ensures easy setup in diverse environments. It operates on 220-240V, 50Hz, and delivers up to 2900 RPM, supporting a wide range of application requirements from home water supply to agricultural and industrial usages. Its noise level remains below 70 dB, offering quiet operation without disturbing surroundings.

FAQs of Overload Protector Pump:

Q: How do I install the Overload Protector Pump for optimal performance?

A: Install the pump horizontally on a stable base using the provided mounting system. Ensure the 1-inch BSP threaded inlet and outlet are securely connected and the electrical supply matches the pumps specification of 220-240V, 50Hz. Self-priming capability simplifies setup, allowing for quick start-up and reliable suction up to 8 meters.Q: What are the benefits of the built-in automatic overload protector?

A: The automatic overload protector prevents the motor from running under excessive current, significantly reducing the risk of overheating and prolonging the pumps service life beyond 5,000 hours. This feature minimizes maintenance requirements and enhances operational safety.Q: Where can the pump be used effectively?

A: This pump is suitable for domestic water supply, industrial fluid transfer, and agricultural irrigation. Its medium discharge pressure, corrosion-resistant construction, and adaptability to various environments make it ideal for homes, factories, farms, and commercial premises, especially across India.Q: What is the process for regular maintenance?

A: Perform routine visual checks for leaks and corrosion. Ensure the cooling and fan system is unobstructed, and inspect mechanical seals periodically. Cleaning the pump and its connecting pipes helps maintain consistent flow and head performance. The overload protection system requires minimal supervision.Q: When should the pumps mechanical seal be replaced?

A: Replace the mechanical seal if you observe persistent fluid leakage or reduced efficiency in pressure and flow rate. Typically, with proper operation and normal conditions, the seal should last several years but check periodically according to the usage frequency.Q: How does the pumps electromagnetic operating principle benefit users?

A: The centrifugal pump uses an electromagnetic principle for efficient fluid movement, providing consistent medium pressure and reliable flow. This ensures stable water supply and transfer with low energy consumption, making it cost-effective for long-term use.Q: What is the maximum fluid temperature the pump can handle safely?

A: The pump operates effectively within a working temperature range of -10C to +50C, accommodating most domestic, industrial, and agricultural fluid transfer scenarios without risk of thermal damage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Overload Protector Category

Hydraulic Overload Protector - 1200 Ton

Price 225000 INR / Piece

Minimum Order Quantity : 01 Piece

Inlet/Outlet : Threaded / Flanged

Application : Other, Mechanical Press, Power Press, Sheet Metal Machinery

Standard : Industrial Grade

Voltage : 220V / 380V AC

Hydraulic Overload Protector

Price 38500 INR / Piece

Minimum Order Quantity : 01 Ton

Inlet/Outlet : Hydraulic Port (Standard G1/4/G3/8)

Application : Other, Mechanical Presses / Stamping Machines

Standard : ISO 9001:2015 / CE Approved

Voltage : Not Required (Hydraulic powered)

Send Inquiry

Send Inquiry