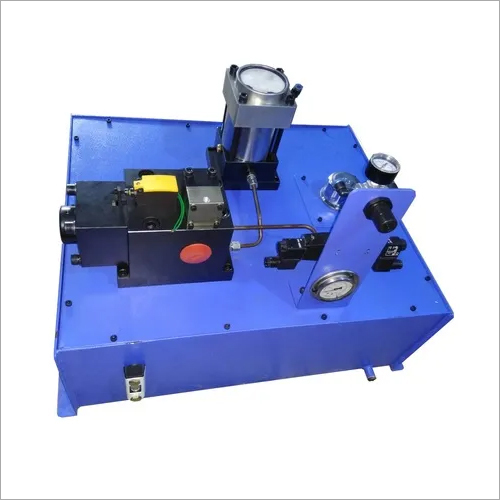

Hydraulic Overload Protector - 1200 Ton

Price 225000 INR/ Piece

MOQ : 01 Piece

Hydraulic Overload Protector - 1200 Ton Specification

- Theory

- Hydraulic Pressure

- Working Temperature

- -10C to +60C

- Discharge Pressure

- Max 1200 Ton

- Voltage

- 220V / 380V AC

- Noise Level

- Low

- Fuel Tank Capacity

- Integrated Small Reservoir

- Mounting Type

- Direct Mount on Press

- Frequency

- 50/60 Hz

- Caliber

- Standard

- Inlet/Outlet

- Threaded / Flanged

- Control System

- Automatic Reset & Release Mechanism

- Flow Rate

- Customizable (As per press requirement)

- Speed

- Standard

- Features

- Accurate Overload Release, Easy Maintenance, Quick Response, Compact Design

- Material

- High-Strength Alloy Steel

- Structure

- Compact Cylinder With Integrated Pump Unit

- Power

- Hydraulic

- Standard

- Industrial Grade

- Fuel Type

- None (Electric Hydraulic)

- Pressure

- Up to 1200 Ton

- Usage

- Mechanical Press Overload Protection

- Application

- Mechanical Press, Power Press, Sheet Metal Machinery

- Seals Type

- High Performance Hydraulic Seals

- Pump Type

- Hydraulic Overload Pump

- Capacity

- Highly Durable For Heavy Load

- Oil Medium

- Anti-wear Hydraulic Oil (ISO VG 46 or equivalent)

- Connection Type

- Suitable For Standard And Non-Standard Presses

- Release Time

- 0.03 Seconds

- Backup System

- Emergency Manual Release

- Reset Mode

- Automatic & Manual

- Service Life

- >5 Million Cycles

- Operating Position

- Horizontal / Vertical Mounting

- Indicator Type

- Mechanical / Electric Signal Available

- Max Press Tonnage

- 1200 Ton

Hydraulic Overload Protector - 1200 Ton Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 2 Week

- Packaging Details

- Boxes

- Main Domestic Market

- All India

About Hydraulic Overload Protector - 1200 Ton

Hydraulic Overload Protector (HOP) is a safety device commonly used in mechanical presses to protect them from overload situations. It acts as a safeguard by preventing damage to the press and its components when excessive force is applied during the forming or stamping process. The HOP utilizes hydraulic pressure to monitor and regulate the force exerted by the press.

FAQ :

Q: How does a Hydraulic Overload Protector work?

A: The Hydraulic Overload Protector consists of a hydraulic cylinder connected to the ram of the press. When the press is in operation, the HOP constantly monitors the force exerted. If the force exceeds a predetermined safe limit, the hydraulic system is activated, causing the HOP to release hydraulic fluid and absorb the excess force. This action prevents damage to the press and tooling.

Q: What are the advantages of using a Hydraulic Overload Protector?

A: The HOP provides several advantages, including:

- Protection against overload situations.

- Increased tooling lifespan.

- Improved productivity.

Q: Can the Hydraulic Overload Protector be adjusted for different applications?

A: Yes, the HOP can be adjusted to accommodate various applications and workpiece materials. The force threshold at which the HOP engages can be set according to the specific requirements of the press operation, ensuring optimal protection while maintaining productivity.

Q: Is regular maintenance required for the Hydraulic Overload Protector?

A: Regular maintenance is essential to ensure the proper functioning of the HOP. It is recommended to follow the manufacturers guidelines regarding maintenance intervals and procedures. Routine inspections, including checking hydraulic fluid levels and system components, help maintain the reliability and effectiveness of the overload protection system.

Q: Are there any limitations or considerations when using a Hydraulic Overload Protector?

A: While the HOP provides valuable protection, it is important to consider its limitations. The HOP is designed to handle sudden or intermittent overloads and may not be effective against prolonged overloads. Additionally, the press operator should be trained on proper usage and aware of the HOPs capabilities to ensure its effective operation.

Advanced Safety for Heavy-Duty Presses

Rely on precise and rapid overload protection with a release time of 0.03 seconds. The system accurately detects excessive loads and initiates a protective release, ensuring both the press equipment and operators are shielded from potential damage.

Adaptable Design and Versatility

With compatibility for both standard and custom presses, horizontal or vertical mounting, and multiple indicator options (mechanical/electric), the Hydraulic Overload Protector fits a vast range of applications including power presses, sheet metal machinery, and high-performance industrial systems.

Long Service Life and Easy Maintenance

Rated for over five million cycles, this protector features high-performance hydraulic seals and integrated small reservoirs for extended durability and minimal upkeep. Its compact cylinder design and direct mounting simplify installation and maintenance for industrial users.

FAQs of Hydraulic Overload Protector - 1200 Ton:

Q: How does the Hydraulic Overload Protector function to guard press machinery?

A: Utilizing advanced hydraulic pressure technology, the protector senses overload situations and initiates an instant release (0.03 seconds), preventing potential damage to presses by disengaging the load through a controlled hydraulic mechanism.Q: What are the available reset modes for this overload protector?

A: Both automatic and manual reset modes are available. After overload protection is triggered, the system can reset itself automatically or operators can manually reset it as needed, offering operational flexibility.Q: When should the overload protector be installed on a press?

A: It is recommended to install the Hydraulic Overload Protector during press setup or retrofitprior to commencing regular operationsso machinery is continuously safeguarded from the outset.Q: Where is the best location for mounting the protector on press machinery?

A: The design allows for direct mounting onto the press in either a horizontal or vertical position, accommodating the specific spatial and structural requirements of your equipment.Q: What is the maintenance process for ensuring optimal performance?

A: Routine inspection of hydraulic fluid (ISO VG 46 or equivalent), periodic seal checks, and monitoring system indicators ensure consistent performance. The systems robust construction and high-quality materials make upkeep straightforward and less frequent.Q: How is overload indicated and what options are available?

A: Overload events are signaled via mechanical or electric indicators, depending on your system configuration. These alerts enable prompt operator response to protect equipment and ensure workplace safety.Q: What are the primary benefits of using this hydraulic overload protector?

A: Key benefits include highly accurate overload detection and release, long-term durability with service life exceeding five million cycles, quick response time, low noise operation, compatibility with varied presses, and simplified installation and maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydraulic Overload Protector Category

Overload Protector Pump

Price 38500 INR / Piece

Minimum Order Quantity : 1 Unit

Caliber : 25 mm

Inlet/Outlet : 1 inch BSP Thread

Mounting Type : Base Mounted

Features : Builtin automatic overload protector, corrosionresistant body, thermal protection, easy installation

Hydraulic Overload Protector

Price 38500 INR / Piece

Minimum Order Quantity : 01 Ton

Caliber : Customizable (Depends on press capacity)

Inlet/Outlet : Hydraulic Port (Standard G1/4/G3/8)

Mounting Type : Flange/Bolted

Features : Highly Reliable, Fast Response, Maintenance Free

Send Inquiry

Send Inquiry