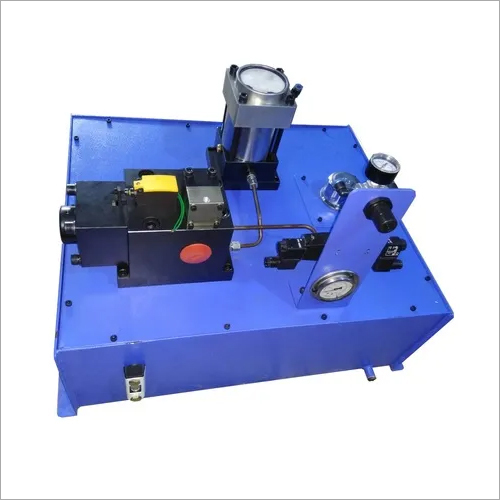

Hydraulic Overload Protector

Price 38500 INR/ Piece

Hydraulic Overload Protector Specification

- Mounting Type

- Flange/Bolted

- Caliber

- Customizable (Depends on press capacity)

- Speed

- Response Time: <10ms

- Inlet/Outlet

- Hydraulic Port (Standard G1/4/G3/8)

- Features

- Highly Reliable, Fast Response, Maintenance Free

- Theory

- Hydraulic Pressure Sensing

- Noise Level

- Silent Operation

- Working Temperature

- -10C to +60C

- Discharge Pressure

- Adjustable Overload Range

- Control System

- Manual Reset / Automatic Reset (Model Dependent)

- Voltage

- Not Required (Hydraulic powered)

- Material

- High-Grade Alloy Steel and Hardened Components

- Structure

- Integrated Hydraulic Cylinder with Relief Valve

- Power

- Mechanical/Hydraulic - No Electrical Power

- Standard

- ISO 9001:2015 / CE Approved

- Pressure

- Up to 400 Bar (Varies by Model)

- Usage

- Press Safety Overload Protection

- Application

- Mechanical Presses / Stamping Machines

- Seals Type

- Nitrile Rubber / Viton

- Capacity

- 10 to 5000 Tons (Model-Specific)

Hydraulic Overload Protector Trade Information

- Minimum Order Quantity

- 01 Ton

- Supply Ability

- 100 Tons Per Month

- Delivery Time

- 3-4 Days

- Packaging Details

- Boxes

- Main Domestic Market

- All India

About Hydraulic Overload Protector

Hydraulic Overload Protector - 200 Ton

We are manufacturer and stockiest of Hydraulic Overload Protector Pump for Mechanical Presses. We have replacement of wide range for reputed makes like SANDSUN ( TAIWAN ), PASCAL ( JAPAN ), KOSMEK ( JAPAN), KONAN ( JAPAN ), SAE JIN ( KOREA ) and KAN-TOU.

-

Overload protector is equipped in press machine to check the hydraulic pressure of cylinder inside the slider.

-

If happened overload, the hydraulic pressure of cylinder will be released

immediately within 3/1000 seconds.

-

When happen overload, in order to protect the press and die, the press will stop working immediately after receiving the signal from limit switch.

-

After happen overload, the air will drive hydraulic pump to supplement normal

working pressure immediately and the press can work normally.

-

It has pressure control valve inside of overload protector. Which can adjust hydraulic pressure automatically and eliminate the impact of rising pressure (which cause by oil temperature rise) in pressing process?

|

AIR SUPPLY(BAR) |

PRESSURE SETTING RATIO |

AREA OF ORIFICE |

PRESSURE SETTING RANGE |

MODEL NO |

CAPACITY |

|

3-5 |

1:50 |

0.7 |

150-250 BAR |

OP03-500 |

UPTO 200 TON |

|

3-5 |

1:70 |

0.5 |

200-350 BAR |

OP03-700 |

|

|

3-5 |

1:90 |

0.4 |

250-450 BAR |

OP03-900 |

|

|

3-5 |

1:50 |

1.7 |

150-250 BAR |

OP06-500 |

UPTO 600 TON |

|

3-5 |

1:70 |

1.2 |

200-350 BAR |

OP06-700 |

|

|

3-5 |

1:90 |

0.9 |

250-450 BAR |

OP06-900 |

|

|

3-5 |

1:40 |

5.4 |

120-200 BAR |

OP10-400 |

UPTO 1200 TON |

|

3-5 |

1:50 |

4.3 |

150-250 BAR |

OP10-500 |

|

|

3-5 |

1:70 |

3.1 |

200-350 BAR |

OP10-700 |

Product Details

|

Area Of Orifice |

0.7-3.1 |

|

Capacity |

300 Ton |

|

Orifice Area |

0.6 Cm2 |

|

Pressure Setting Ratio |

1.50-1.70 |

|

Required Overload press |

300 Kg/Cm2 |

|

Pump Type |

air driven hydraulic pump |

|

Brand |

Omson |

|

Air Supply |

5 KG/CM2 |

|

Air Consumption |

14CFM |

|

Model Number |

OP03 |

Advantages of Hydraulic Overload Safety Pump:

- Stop Press operation immediately and protect press from major breakdown

- Protect Die during overload situation

- Protect Components

- Easily ejection component from die

- Just single Reset Push Button and resume press operation, save time and increase productivity

- Extend Tool Life also indicate in case tool needs to refurbish

- Reduce connection clearances

- Alert during excessive off-center loads

Superior Safety for Press Operations

Designed to safeguard mechanical presses and stamping machines, the Hydraulic Overload Protector offers robust relief against unforeseen overloads. Its integrated hydraulic cylinder with a pressure relief valve automatically senses and mitigates excess hydraulic pressure, responding in less than 10 milliseconds. This ensures not only machine uptime but also operator safety, making it essential in high-capacity industrial setups.

Reliable, Maintenance-Free Performance

With a service life exceeding one million cycles and zero leakage under standard conditions, the Hydraulic Overload Protector stands out for its consistent reliability. Its anti-corrosive coating, nitrile rubber or Viton seals, and hardened alloy steel construction guarantee long-term integrity in demanding environments. Routine maintenance is virtually eliminated, supporting continuous operation in busy manufacturing lines.

Flexible Installation and Operation

Available with customizable calibers and mounting options, the overload protector is adaptable to most hydraulic presses and stamping machines. Choose between flange or bolted mounting, BSP or NPT connection threads, and manual or automatic reset types as suited to operational needs. With silent mechanical/hydraulic power and ISO/CE accreditation, it streamlines integration for manufacturers, dealers, and service providers across India.

FAQs of Hydraulic Overload Protector:

Q: How does the Hydraulic Overload Protector enhance safety during press operations?

A: By integrating pressure relief sensing, the protector instantly detects and reacts to excessive hydraulic forces, automatically safeguarding the equipment and operators from overload situations. Its fast response ensures machine integrity and minimizes the risk of damage or accidents.Q: What process is used to reset the overload protector after activation?

A: The reset method depends on the specific model: it can be reset manually by an operator or automatically after the overload condition is cleared, enabling rapid resumption of operation without complex procedures.Q: Where can the Hydraulic Overload Protector be installed?

A: It is suitable for mechanical presses and stamping machines in industrial environments, with mounting options including flange or bolted configurations and connection threads in BSP or NPT, allowing versatile placement on various hydraulic setups.Q: What is the recommended usage for this overload protector?

A: Designed primarily for press safety and overload protection, it is ideal for applications involving high-pressure hydraulic systems, such as stamping, forming, and mechanical presses within manufacturing plants.Q: What benefits does it offer compared to conventional overload mechanisms?

A: Key advantages include silent operation, zero leakage, rapid response times under 10 milliseconds, maintenance-free design, and a service life exceeding one million cyclescombined with robust anti-corrosive construction for long-lasting dependability.Q: How is the discharge pressure adjusted to suit different press capacities?

A: Discharge pressure settings are adjustable within each models customizable overload range, allowing precise tuning to correspond with the presss capacity and operational requirements for optimal safety.Q: What type of hydraulic oil and seal materials are compatible with this protector?

A: It is compatible with ISO VG 46 hydraulic oils and uses high-quality Nitrile Rubber or Viton seals, ensuring reliable operation and resistance to wear, chemical exposure, and temperature extremes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Overload Protector Category

Overload Protector Pump

Price 38500 INR / Piece

Minimum Order Quantity : 1 Unit

Pressure : Other, 0.7~4 Bar

Application : Other, Domestic, Industrial, Agricultural

Speed : 2900 RPM

Material : Cast Iron and Brass

Hydraulic Overload Protector - 1200 Ton

Price 225000 INR / Piece

Minimum Order Quantity : 01 Piece

Pressure : Other, Up to 1200 Ton

Application : Other, Mechanical Press, Power Press, Sheet Metal Machinery

Speed : Standard

Material : HighStrength Alloy Steel

Send Inquiry

Send Inquiry