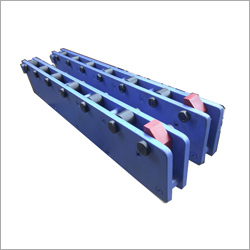

Quick Die Change System

Price 250000 INR/ Set

MOQ : 01 Set

Quick Die Change System Specification

- Phase

- Three Phase

- Shape

- Rectangular module/block

- Product Type

- Quick Die Change System

- General Use

- For quick and safe die change process in stamping presses

- Material

- High strength alloy steel, Die-cast aluminum

- Type

- Hydraulic Quick Die Change System

- Capacity

- Supports die weight up to 20 Tons (varies by model)

- Weight (kg)

- Approx. 300 - 1200 kg (depending on model)

- Computerized

- No

- Automatic

- Yes

- Touch Screen

- Optional

- Control System

- Hydraulic/Electro-hydraulic control module

- Surface Treatment

- Powder coated and hardened plating

- QC System

- Inbuilt safety and diagnostic system

- Tolerance

- 0.05 mm

- Drawing

- Available on request

- Voltage

- 220/380V, 50/60Hz

- Dimension (L*W*H)

- Customized as per application

- Feature

- Improves productivity, Ensures operator safety, Reduces die change downtime

- Color

- Standard industrial yellow/black

- Die Lifters

- Rolling balls or hydraulic cylinders

- Installation

- On-site support available

- Clamping Force

- Adjustable (model-dependent)

- Safety Features

- Dual safety interlock, emergency stop button

- Power Source

- Electric / Pneumatic / Hydraulic

- Operating Pressure

- 5~7 kg/cm² (as per system design)

- Operating Temperature

- 0°C to 50°C

- OEM/ODM

- Supported

- Maintenance

- Low, Easy to Service

- Application

- Stamping press, injection molding, forging press

Quick Die Change System Trade Information

- Minimum Order Quantity

- 01 Set

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 3-4 Days

- Packaging Details

- Boxes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Quick Die Change System

We deliver this Quick Die Change System which is featured with green, yellow & red LEDs, 4 switches and moving die lock. The offered is highly acclaimed among clients due to its many automatic functions and multi language interfaces. Also, it is known for its display automatic and operator controller functions. For preventing the accident, this panel contains electric supply key switch. Apart from this, the provided Quick Die Change System is perfect for displaying the situation of the clamps.

Key points:

Key points:

- Operated with safety and convenience to QDCS on press

- Has corrosion proof closure

- Easy to control

Transforming Die Change Efficiency

Experience significant productivity gains with our Quick Die Change System, which enables safe and fast die replacements in high-volume production lines. The robust hydraulic/electro-hydraulic control module ensures seamless integration with stamping and forging presses, reducing downtime and labor demands. A dual safety interlock combined with an emergency stop feature guarantees exceptional operator protection, making your workspace both efficient and secure.

Reliable Performance with Custom Options

Rely on a high-quality, customizable system tailored to your unique facility requirements. Designed with tolerance precision of 0.05 mm and constructed from durable alloy steel and die-cast aluminum, our modules can withstand rigorous manufacturing environments. Powder coating and hardened plating extend service life, while optional touch screen control makes monitoring and adjustments simple. Installation and after-sales support are provided for a seamless transition.

FAQs of Quick Die Change System:

Q: How does the quick die change system improve operational efficiency?

A: By allowing for rapid, automatic die changes on stamping and forging presses, the system cuts down on machine downtime, leading to higher productivity and reduced labor requirements in manufacturing processes.Q: What safety features are included in the quick die change system?

A: The system is equipped with dual safety interlocks and an emergency stop button, alongside an inbuilt safety and diagnostic QC system, ensuring maximum operator protection and fault detection during the die change process.Q: When should the clamping force be adjusted, and how is it set?

A: Clamping force should be adjusted based on the specific die and press requirements for each operation. The force can be easily set on the control module, with settings available depending on the selected system model.Q: Where can this system be installed, and is on-site support provided?

A: The quick die change system can be installed on stamping presses, injection molding, or forging presses in a variety of industrial settings. On-site installation support and training are available to ensure smooth commissioning.Q: What power sources are compatible with the system?

A: This system is versatile, running on electric, pneumatic, or hydraulic power sources, with a standard voltage of 220/380V and frequencies of 50/60Hz, suitable for most industrial environments.Q: How often is maintenance required, and what is the process?

A: Featuring a low-maintenance design, the system requires only periodic checks and servicing of hydraulic oil and moving parts. Maintenance is straightforward, with most components easy to access and replace as needed.Q: What are the main benefits of using this system in manufacturing?

A: Primary benefits include enhanced operator safety, significant reduction in die changeover time, improved equipment longevity, and higher productivity, all while supporting die weights up to 20 tons (depending on the model).

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Quick Die Changing System Category

Die Arm

Price 24300 INR / Piece

Minimum Order Quantity : 1 Unit

Touch Screen : No

General Use : Die Casting Mould Handling

Product Type : Die Arm

Type : Other, Linear/Parallel Movement Type

Quick Die Clamping System

Price 275000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Touch Screen : No

General Use : Die Clamping in Press Machines

Product Type : Quick Die Clamping System

Type : Other, Hydraulic / Mechanical / Pneumatic

Die Lifter

Price 28000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Touch Screen : No

General Use : Mould and Die Handling

Product Type : Die Lifter

Type : Other, Hydraulic or Mechanical Roll Type

Send Inquiry

Send Inquiry