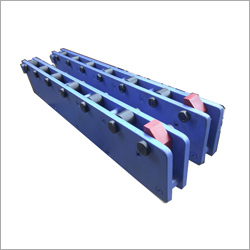

Die Lifter

Price 28000.00 INR/ Piece

Die Lifter Specification

- Shape

- Rectangular or Customized

- Diameter

- Standard 40mm / Customized

- Product Type

- Die Lifter

- General Use

- Mould and Die Handling

- Material

- Alloy Steel / Hardened Steel

- Type

- Hydraulic or Mechanical Roll Type

- Capacity

- 1000 kg/pc (customized available)

- Weight (kg)

- Varies as per model

- Computerized

- No

- Automatic

- No

- Touch Screen

- No

- Control System

- Manual

- Surface Treatment

- Black Oxide Coating or Plated

- QC System

- ISO 9001:2015 Certified

- Tolerance

- 0.02 mm

- Drawing

- Available on Request

- Dimension (L*W*H)

- Custom Sizes Available

- Feature

- Heavy Load Bearing, Low Friction, Easy Installation

- Color

- Black / Silver (Plated)

- Installation Method

- Bolt-On / Drop-In

- Roller Type

- Needle Roller / Ball Roller

- Application Field

- Press Machine, Mold Change System

- Load Direction

- Bidirectional

- Operating Temperature

- -20°C to +70°C

Die Lifter Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 3-4 Days

- Packaging Details

- BOXES

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Die Lifter

Die Lifter is a rectangular cross section & can be fitted in Slot of bolster. Length of die-lifter unit is 1250 mm & four single acting, load return cylinders are fitted in it. Roller is fitted on every piston which have specific orientation No. of die-lifter units can connected to other as per slot length in the bolster.

Product Details

Length | 1850 mm |

Material | SS |

Load Capacity | 5 Ton |

Capacity | 3-4 ton |

Brand | Omson |

Roller Materials | Hydraulic |

Versatile Application and High Performance

Suitable for use in press machines and mold change systems, this die lifter is engineered to handle demanding environments and varied loads. Its heavy load-bearing capability ensures reliable and efficient transfer or handling of molds and dies. Customizable sizes and diameters make it adaptable for diverse industrial requirements, offering flexibility in installation and application.

User-Friendly Installation and Operation

With options for bolt-on or drop-in installation, the die lifter simplifies setup and integration into existing systems. Manual operation requires no automation or computerized control, reducing complexity and maintenance. The robust construction with black oxide or plated finishes provides excellent durability and resistance to harsh conditions, ensuring consistent performance over time.

FAQs of Die Lifter:

Q: How is the Die Lifter installed on a press machine or mold change system?

A: The Die Lifter can be installed using either the bolt-on or drop-in method, allowing for flexible adaptation to your setup. Detailed installation instructions and drawings are available on request to ensure proper alignment and safety.Q: What are the primary benefits of using Needle Roller or Ball Roller types in this Die Lifter?

A: Both Needle Roller and Ball Roller types provide low friction, enabling smooth and effortless movement of heavy molds or dies. This reduces manual effort and enhances productivity during mold changes or material handling.Q: When should I choose a customized capacity or size for my application?

A: Customized capacity or size is recommended when your operational requirements exceed the standard 1000 kg per unit or when your equipment dimensions differ from available specifications. Our team can tailor the product to suit specific industrial needs.Q: Where can this Die Lifter be used apart from press machines?

A: In addition to press machines, the Die Lifter can be effectively used in a variety of mold change systems and die handling applications in automotive, appliance manufacturing, metal stamping, and related industries.Q: What is the maintenance process for the Die Lifter?

A: Maintenance is straightforward due to its manual operation and robust surface treatments. Regular cleaning and periodic inspection for wear or damage are recommended to maintain optimal performance and extend service life.Q: What makes this Die Lifter suitable for heavy industrial use?

A: Manufactured from alloy or hardened steel, this lifter boasts high load capacity, superior durability, and precise tolerances. The heavy load-bearing design is perfect for repeated operations in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Quick Die Changing System Category

Die Arm

Price 24300 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : Other, Adjustable Extension Arm, Heavy Duty Construction

Surface Treatment : Other, Powder Coated

Phase : Single / Three Phase

QC System : Standard Factory QC

Quick Die Clamping System

Price 275000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : Other, Quick Changeover, High Clamping Force, Safety Interlock

Surface Treatment : Other, Powder Coated / Plated

Phase : Single/Three Phase (if powered)

QC System : 100% Inspection

Quick Die Change System

Price 250000 INR / Set

Minimum Order Quantity : 01 Set

Feature : Other, Improves productivity, Ensures operator safety, Reduces die change downtime

Surface Treatment : Other, Powder coated and hardened plating

Phase : Three Phase

QC System : Inbuilt safety and diagnostic system

Send Inquiry

Send Inquiry