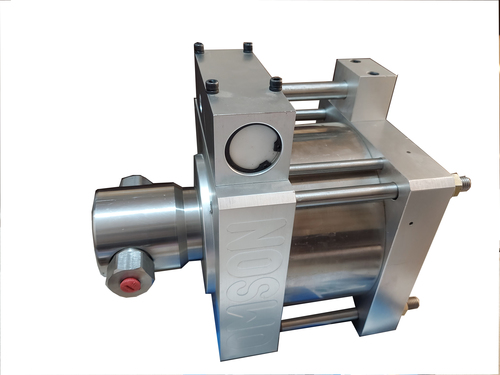

Hydraulic Overload Protector Pump

Price 48000.00 INR/ Piece

Hydraulic Overload Protector Pump Specification

- Control System

- Automatic/Manual Release

- Voltage

- 220V / 380V

- Noise Level

- 70 dB

- Mounting Type

- Base Mounted

- Features

- Compact Design, Easy Installation, High Reliability

- Frequency

- 50/60 Hz

- Working Temperature

- -10C to 70C

- Inlet/Outlet

- G 1/2 Threaded

- Discharge Pressure

- Up to 15 MPa

- Caliber

- 1/2 inch

- Theory

- Hydraulic Overload Protection

- Flow Rate

- 5-15 L/min

- Head Size

- 16 meters

- Max Suction

- 3-5 meters

- Speed

- 1440 rpm

- Fuel Tank Capacity

- 8-12 L

- Material

- Cast Iron/Steel

- Structure

- Piston Pump

- Power

- 0.75 kW

- Standard

- ISO 9001:2015

- Fuel Type

- Hydraulic Oil

- Pressure

- 8-15 MPa

- Usage

- Press Machine / Hydraulic Press

- Application

- Hydraulic Press Overload Protection

- Suction Type

- Single Stage

- Seals Type

- Hydraulic seals (NBR/PU)

- Priming

- Self-Priming

- Pump Type

- Hydraulic Pump

- Capacity

- 5-10 L

Hydraulic Overload Protector Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 3-4 Days

- Main Domestic Market

- All India

About Hydraulic Overload Protector Pump

- Pressure and flow requirements.

- Power source.

- System compatibility.

Superior Overload Protection with Fast Response

This hydraulic overload protector pump safeguards press machines with its advanced piston structure and rapid response time of less than 0.2 seconds. Designed for reliability, it instantly relieves excessive pressure to prevent equipment damage or downtime, ensuring seamless production environments in automotive, metalworking, and manufacturing sectors.

Versatile Operating Range and Durability

Operating at pressures up to 15 MPa and temperatures between -10C and 70C, the pump accommodates a variety of industrial demands. Its durable cast iron or steel body, NBR/PU hydraulic seals, and IP54 protection class enable use in challenging environments. Coupled with a service life exceeding one million cycles, this pump provides lasting value and performance.

User-Friendly Design and Installation

Ease of installation is a priority, with threaded G 1/2 inches inlet/outlet and self-priming capabilities. The compact, base-mounted design, air-cooled system, and optional automatic/manual controls simplify integration into existing setups. Factory-preset relief valves can be adjusted upon request, meeting unique operational requirements effortlessly.

FAQs of Hydraulic Overload Protector Pump:

Q: How does the hydraulic overload protector pump protect press machines during operation?

A: The pump rapidly senses overload conditions and responds in under 0.2 seconds by relieving excessive hydraulic pressure, preventing machinery damage or operational interruptions. This is achieved through a factory-preset (and adjustable) relief valve, ensuring your hydraulic press runs safely and efficiently.Q: What types of hydraulic fluids are compatible with this overload protector pump?

A: The pump is designed for mineral hydraulic oil and synthetic oils within a viscosity range of 32-68 cSt, offering flexibility based on application requirements. Always ensure fluids meet these specifications for optimal performance and longevity of the pump.Q: When should I consider adjusting the factory-preset relief valve setting?

A: While the relief valve comes preset for most general applications, adjustments may be required for specialized processes or to accommodate different machinery characteristics. Any modification should be performed by qualified personnel or upon consultation with the manufacturer or dealer.Q: Where can this hydraulic overload protector pump be installed?

A: Thanks to its compact, base-mounted construction and IP54 protection rating, the pump can be installed in diverse industrial settings, including factories, workshops, and manufacturing lines using press machines or hydraulic presses. It withstands ambient humidity up to 90% RH and temperatures from -10C to 70C.Q: What is the process for installing and commissioning the pump?

A: Begin by securely mounting the pump to a stable base near your hydraulic press. Connect the G 1/2 threaded inlet and outlet, fill the reservoir with compatible hydraulic oil, and confirm all seals are intact. Power it using a compatible voltage (220V or 380V), then follow the control systems instructions for initial setupautomatic or manual as desired.Q: How can users benefit from the high reliability and service life of this pump?

A: With a service life of over one million cycles, the pump ensures long-term, maintenance-minimal protection for hydraulic presses. Its dependable design reduces the risk of costly downtime, machinery repairs, and production losses, making it a preferred choice for manufacturers and service providers alike.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machine Pumps Category

Kosmek Pneumatic Oil Pump

Price 68500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, Max 7 MPa (Oil Outlet)

Theory : Other, Reciprocating (Double Acting) Pneumatic Oil Pump

Power : Other, Compressed Air Driven

Flow Rate : Approx. 0.32 L/min (@ 0.5 MPa air pressure)

PASCAL - HPH6308

Price 68500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Low Pressure

Theory : Centrifugal Pump

Power : Other, 7.5 HP

Flow Rate : 1100 L/min

HYDRAULIC BOOSTER

Price 128500.0 INR / Number

Minimum Order Quantity : 1 Number

Pressure : Other, Maximum 8 Bar

Theory : Other, Hydraulic Booster Theory

Power : Other, 2.2 kW

Flow Rate : 40 L/min

SANDSUN - VS08-760

Price 38500 INR / Piece

Minimum Order Quantity : 1 Piece

Pressure : Other, 4~7 kg/cm

Theory : Other, Vacuum Ejector

Power : Other, Pneumatic (no electric motor)

Flow Rate : 760 L/min

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS