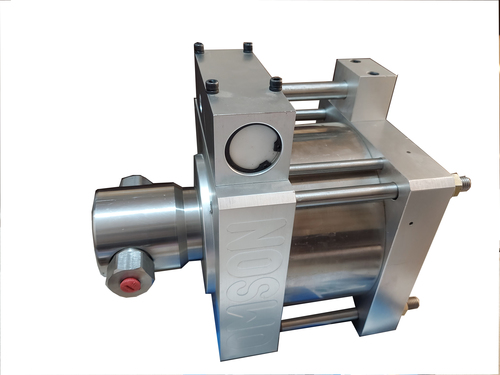

SLIDE LOCKING PUMP - PE07-PRS

Price 58500.0 INR/ Set

SLIDE LOCKING PUMP - PE07-PRS Specification

- Working Temperature

- -10C to 80C

- Caliber

- 25 mm

- Frequency

- 50 Hz

- Voltage

- 220-240V

- Head Size

- 18 meters

- Max Suction

- 8 meters

- Noise Level

- <60 dB

- Features

- Sturdy Construction, Leak Proof Seals, Slide Locking Mechanism

- Inlet/Outlet

- 25 mm / 25 mm (1 inch)

- Speed

- 2900 RPM

- Flow Rate

- 60 L/min

- Discharge Pressure

- 1.8 bar

- Control System

- Manual On/Off

- Theory

- Centrifugal Pump

- Mounting Type

- Base Mounted

- Material

- Cast Iron Body with Brass Impeller

- Structure

- Single Stage

- Power

- 0.75 kW (1 HP)

- Standard

- ISO Certified

- Fuel Type

- Electric

- Pressure

- 1.8 bar

- Usage

- Industrial, Agriculture, Water Supply

- Application

- Clean Water Pump, Liquid Transfer

- Suction Type

- Slide Locking Type

- Seals Type

- Mechanical Seal

- Priming

- Self-priming

- Pump Type

- Slide Locking Pump

- Capacity

- 60 liters/minute

SLIDE LOCKING PUMP - PE07-PRS Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 3-4 Days

- Main Domestic Market

- All India

About SLIDE LOCKING PUMP - PE07-PRS

OMSON Slide lock system has been particularly designed for a stamping machine and die. It is the essential device for safety maintenance works. Securely locking the press slide at the random position between T.D.C. and B.D.C., Slide lock system prevents a physical injury to people or damage to diesReliable Performance Across Multiple Applications

With industrial-grade construction and ISO certification, the SLIDE LOCKING PUMP - PE07-PRS is suitable for agriculture, water supply networks, and clean water transfer. The closed brass impeller design and anti-corrosive coated body ensure durability, while the pumps mechanical seal and slide locking mechanism minimize operational risks and leakage.

Efficient Centrifugal Operation and Safety

Operating at 220-240V and 50 Hz frequency, the pump utilizes centrifugal theory to deliver a steady flow of up to 60 L/min. Protection class IP44 safeguards electrical components, and its insulation class F further enhances safety. Manual On/Off control supports consistent operation with minimized downtime.

Ease of Use and Maintenance

Base mounted and featuring a slide locking suction type, the pump allows straightforward installation and removal. The 1.5-meter cable length and self-priming design simplify set-up and use, while leak-proof mechanical seals mean reduced maintenance requirements over time.

FAQs of SLIDE LOCKING PUMP - PE07-PRS:

Q: How do I install the SLIDE LOCKING PUMP - PE07-PRS?

A: To install the pump, secure it to a stable base using the mounting provisions, connect the 25 mm inlet and outlet with appropriate plumbing, attach the 1.5-meter cable to a 220-240V power source, and ensure the slide locking suction mechanism is engaged for effective priming.Q: What is the main benefit of the slide locking suction mechanism?

A: The slide locking suction mechanism ensures secure attachment of the suction hose, reducing leakage risks and improving overall priming reliability, which is critical for clean water and liquid transfer operations.Q: When should the pump be used for optimal performance?

A: Use the SLIDE LOCKING PUMP - PE07-PRS within its operational temperature range (-10C to 80C) and acceptable pressure and flow rates to maximize efficiency. Ideal conditions include clean water tasks in industrial, agricultural, or general water supply settings.Q: Where is the SLIDE LOCKING PUMP - PE07-PRS typically applied?

A: This pump is commonly installed in agricultural fields, industrial facilities, and municipal water supply projects throughout India, where clean water transfer and reliable, leak-proof operation are important.Q: What process does the pump utilize for priming and operation?

A: The pump employs a centrifugal design with self-priming capability, drawing water efficiently through its slide locking suction. The closed brass impeller ensures consistent flow, while the mechanical seal prevents leaks during operation.Q: How does the anti-corrosive powder coating benefit the pump?

A: The anti-corrosive powder-coated finish protects the cast iron body from rust, increasing the pumps longevity and reliability when used frequently in outdoor or harsh environments.Q: Can the pump be controlled remotely?

A: No, the SLIDE LOCKING PUMP - PE07-PRS features a manual On/Off control system. For remote management, additional external control systems would need to be installed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Machine Pumps Category

Kosmek Pneumatic Oil Pump

Price 68500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 180 ml (Oil Chamber)

Application : Other, Hydraulic Pumping for Fixture Clamping, Industrial Automation

Features : Compact, Lightweight, Low Noise, Maintenance Free

Voltage : No electrical power required (pneumatic operated)

PASCAL - HPH6308

Price 68500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 1100 L/min

Application : Other, Water Supply, Agriculture, Irrigation

Features : Heavy Duty, High Efficiency, Easy Installation

Voltage : 220V / 50Hz

HYDRAULIC BOOSTER

Price 128500.0 INR / Number

Minimum Order Quantity : 1 Number

Capacity : 40 Liters/min

Application : Other, Water Supply, Pressure Boosting, Irrigation

Features : Corrosion Resistance, Easy Installation, High Efficiency

Voltage : 220V

FORWELL - FP1014U

Price 85000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 2 m/hr

Application : Other, Industrial, Agricultural, Domestic

Features : Corrosion Resistant, High Efficiency, Durable

Voltage : 220V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS