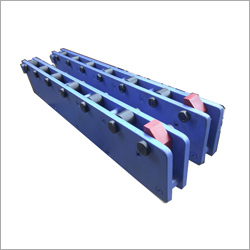

Quick Die Clamping System

Price 275000.00 INR/ Piece

Quick Die Clamping System Specification

- Phase

- Single/Three Phase (if powered)

- Shape

- Rectangular / Block

- Torque

- Up to 60 Nm

- Product Type

- Quick Die Clamping System

- General Use

- Die Clamping in Press Machines

- Material

- Alloy Steel / Hardened Steel

- Type

- Hydraulic / Mechanical / Pneumatic

- Capacity

- Standard to Heavy Duty (varies by model)

- Weight (kg)

- Varies (Approx. 12-45 kg per clamp)

- Computerized

- No

- Automatic

- Yes

- Touch Screen

- No

- Control System

- Manual/Automatic Controls

- Surface Treatment

- Powder Coated / Plated

- QC System

- 100% Inspection

- Tolerance

- 0.01 mm

- Drawing

- Available On Request

- Voltage

- 230V / 415V AC (for hydraulic/electric models)

- Dimension (L*W*H)

- Model Dependent (e.g. 180x86x70 mm)

- Feature

- Quick Changeover, High Clamping Force, Safety Interlock

- Color

- Blue/Grey/Custom

Quick Die Clamping System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- Days

- Packaging Details

- Boxes

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Quick Die Clamping System

QUICK DIE CLAMPING SYSTEM (QDC):- It is a must for the manufactures that their plant operation is capable of compromising the needs of decreasing production lot and increasing variation of products and at the same time shortening of delivery time & lowering the production cost.

This high-performance, compact OMSON Clamping unit can generate high hydraulic pressure from compressed air. The air/hydraulic balance design maintains a constant pressure without consuming any energy. At the balanced condition, there is no air consumption so that there is no power loss or temperature rise compared to an electric pump.

In the event of an air supply failure, the hydraulic pressure shall be retained by the check valve built-in the discharge side. Once pressure is lost, the unit immediately responds to pump up the pressure to the designated level.

Product Details

|

No of Circuit |

3 |

|

Power Consumption |

5 kg air pressure |

|

Brand |

Omson |

|

Size |

8 x 12 x 10 |

|

Automation Grade |

Automatic |

|

Weight |

10 kg |

|

Voltage |

24 v DC |

Fast, Reliable Die Clamping Solution

Engineered for heavy-duty applications, the Quick Die Clamping System delivers rapid changeovers, reducing downtime in automotive, sheet metal, and stamping lines. With its high clamping force, 100% QC inspection, and cycle time under 10 seconds per clamp, this system boosts your production efficiency while ensuring uncompromised safety and durability.

Flexible Installation and Operation

This system offers both standard and custom mounting options, fitting seamlessly into various press machine setups. It supports hydraulic, mechanical, or pneumatic actuation, with manual or automatic controls available, ensuring compatibility with your operational requirements whether you need a single clamp or a complete setup tailored to your process.

Safety and Maintenance Advantages

Featuring integrated safety interlocks and low-maintenance components, the Quick Die Clamping System minimizes risks to operators and maintenance teams. Powder-coated or plated for extended life and reliability, this clamp is designed to function consistently in challenging conditions while keeping upkeep straightforward and cost-effective.

FAQs of Quick Die Clamping System:

Q: How does the Quick Die Clamping System improve die changeover times?

A: The system ensures rapid die changeover with a clamping cycle time of less than 10 seconds per clamp, significantly reducing downtime in press machine operations and increasing throughput efficiency.Q: What industries and applications are best suited for this clamping system?

A: The Quick Die Clamping System is ideal for heavy-duty applications in the automotive, sheet metal, and stamping industries, where fast, reliable, and high-force clamping is essential for productivity and safety.Q: When should the Quick Die Clamping System be used instead of manual clamps?

A: Use this system when your operation requires quick die changes, high clamping force, enhanced safety interlocks, and consistent performanceespecially in high-frequency or heavy-duty press applications where manual clamps cannot meet cycle, safety, or force requirements.Q: Where can this clamping system be installed?

A: It can be installed on a variety of press machines, with options for both standard and custom mounting to suit different machine sizes and configurations. Model-dependent dimensions and flexibility ensure a fit for most industrial press setups.Q: What is the maintenance process for the Quick Die Clamping System?

A: Maintenance is minimal due to its robust alloy/hardened steel construction and powder-coated or plated finish. Routine checks and lubrication, as specified by the manufacturer, are recommended for optimal reliability and longevity.Q: How does the built-in safety interlock work?

A: The integrated safety interlock prevents unintentional release or clamping, ensuring that die changes occur safely and only under proper operational conditions. This reduces the risk of accidents during high-frequency operation.Q: What are the power requirements and control options available?

A: The system supports both hydraulic and electric models that operate on 230V or 415V AC, in single or three-phase configurations. Users can choose between manual or automatic control systems to best fit their production environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Quick Die Changing System Category

Die Arm

Price 24300 INR / Piece

Minimum Order Quantity : 1 Unit

Capacity : Up to 1.5 Ton (customizable)

Color : Blue / Custom

Product Type : Die Arm

Material : Other, Mild Steel

Quick Die Change System

Price 250000 INR / Set

Minimum Order Quantity : 01 Set

Capacity : Supports die weight up to 20 Tons (varies by model)

Color : Standard industrial yellow/black

Product Type : Quick Die Change System

Material : Other, High strength alloy steel, Diecast aluminum

Die Lifter

Price 28000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 1000 kg/pc (customized available)

Color : Black / Silver (Plated)

Product Type : Die Lifter

Material : Other, Alloy Steel / Hardened Steel

Send Inquiry

Send Inquiry