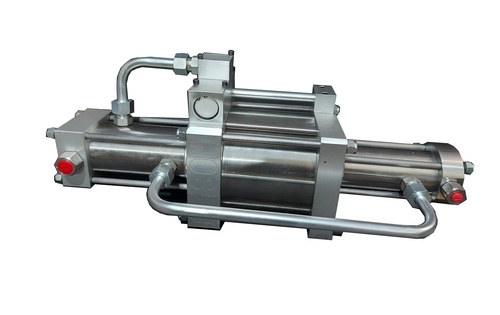

OXYGEN GAS BOOSTER

Price 235000.00 INR/ Set

OXYGEN GAS BOOSTER Specification

- Max Suction

- Up to 7 bar

- Mounting Type

- Panel or Skid

- Control System

- Manual / Semi-automatic

- Head Size

- Customizable

- Discharge Pressure

- Max 210 bar

- Flow Rate

- 5-120 Nm/hr

- Noise Level

- <78 dB(A)

- Working Temperature

- -20C to +60C

- Speed

- Variable (Depending on Air Drive)

- Theory

- Gas Compression

- Inlet/Outlet

- 1/2 or as specified

- Caliber

- DN8 DN20

- Features

- Explosion-proof, Oil-free compression, Compact design, Easy to install, Low maintenance

- Material

- Stainless Steel 316, Brass (Oxygen Service)

- Structure

- Portable Skid Mounted

- Power

- Pneumatically Driven

- Standard

- Oxygen Service Standards, ISO Certified

- Pressure

- Up to 210 bar (3000 psi)

- Usage

- Oxygen Gas Boosting

- Application

- Industrial, Medical Oxygen Cylinders Filling, Laser Cutting, Steel Plants

- Suction Type

- Single Stage

- Seals Type

- Special Oxygen Compatible Seals

- Priming

- Self-Priming

- Pump Type

- Gas Booster Pump

- Capacity

- Custom on Request

OXYGEN GAS BOOSTER Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 4 Days

- Main Export Market(s)

- Asia, Africa, Middle East

- Main Domestic Market

- All India

About OXYGEN GAS BOOSTER

With OMSON gas boosters, pure compressed air is used as the driving power, and a gas booster pump as the pressure source. In addition to oxygen, Nitrogen, N2O, Argon, helium, CO2 and other gases are used as the pressurized medium. The output pressure is dependent upon the pressure of the driving gas. The pressurized gas pressure can be obtained by adjusting the driving gas pressure. When the pressures of the driving gas source and pressurized gas are balanced, the pneumatic booster pump will automatically stop, stabilizing the gas pressure at the preset value. Its features include explosion-proofing, environmental protection, adjustable output pressure, energy saving, simple operation, and reliable performance.

Plug & Play, No Electricity Needed

The oxygen gas booster offers a true plug-and-play experience, operating entirely on compressed air with no electrical connection required. This makes it suitable for use in challenging environments and locations where electrical installations are impractical or undesirable. Its compact, skid-mounted frame can be set up quickly indoors or outdoors, without the need for a dedicated foundation.

High Purity, Oil-Free Compression

Our booster uses an oil-free compression system and oxygen-compatible seals, ensuring the gas remains uncontaminated from inlet to cylinder. This design meets stringent international standards and is ideal for high-purity applications, such as medical oxygen filling, laser cutting, and steel manufacturing.

Efficient & Safe Cylinder Filling

Engineered for safety, the booster incorporates integrated overpressure relief valves, explosion-proof construction, and a manual or semi-automatic control system. Capable of filling multiple oxygen cylinders up to 210 bar, the system maximizes efficiency through self-priming and variable speed operation tailored to your air supply pressure.

FAQ's of OXYGEN GAS BOOSTER:

Q: How does the air-driven mechanism of the oxygen gas booster operate?

A: The booster utilizes compressed air-rather than electricity-to drive its gas compression process. This makes it suitable for settings where electrical power is limited, while ensuring inherent explosion safety.Q: What are the main advantages of oil-free, oxygen-compatible construction?

A: Oil-free operation eliminates the risk of contaminating the oxygen stream, maintaining high purity for sensitive applications. Special oxygen-compatible seals further enhance safety and longevity.Q: When is it appropriate to use this booster for cylinder filling?

A: The gas booster is ideal for filling oxygen cylinders in medical, industrial, and laboratory settings whenever high-purity, high-pressure oxygen is required. It supports multi-cylinder setups and can operate indoors or outdoors within -20C to +60C.Q: Where can the gas booster be installed, and what is required for setup?

A: Thanks to its portable, skid-mounted design and plug-and-play configuration, it can be installed anywhere with access to a compressed air supply. No foundation work or specialized installation is needed.Q: What is the typical service life and maintenance requirement?

A: Engineered for more than 10,000 hours of operational life with proper maintenance, the booster requires only routine check-ups, largely because its oil-free, air-cooled design helps minimize service interventions.Q: How does the built-in safety system work during use?

A: Integrated overpressure relief and explosion-proof features ensure that the system operates safely even under demanding pressure conditions, protecting equipment and personnel during gas boosting and cylinder filling.Q: What benefits does the booster offer for distributors and service providers in India?

A: Distributors and service providers benefit from the product's compliance with ISO and Oxygen Service Standards, ease of installation, minimal maintenance needs, and suitability for a variety of demanding oxygen applications, enhancing operational safety and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in GAS BOOSTERS Category

NITROGEN GAS BOOSTER

Price 165000.00 INR / Number

Minimum Order Quantity : 1 Number

Pressure : High Pressure

Structure : Piston Pump

Fuel Type : Other

Theory : Reciprocating Pump

GAS BOOSTER

Price 165000.0 INR / Set

Minimum Order Quantity : 1 Set

Pressure : High Pressure

Structure : Diaphragm Pump

Fuel Type : Other

Theory : Reciprocating Pump

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS